ICF Construction – What You Need to Know About an ICF Home

This post may contain affiliate links. Read my full disclosure here.

When we were researching our “forever home”, we chose ICF (Insulated concrete Form) construction for a number of reasons. It’s tough, energy efficient and should last a lifetime with minimal upkeep.

Table of contents

What is ICF (Insulated Concrete Forms)?

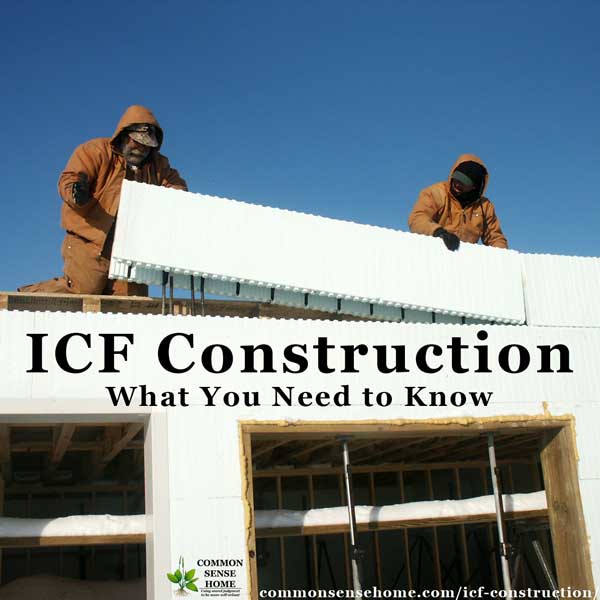

ICF (Insulated Concrete Forms) are premade forms that fit together like Legos or large interlocking blocks. The outside of the form is flat sheets of foam insulation.

These sheets are connected with plastic framework. During construction, the ICF blocks are fitted together, laced with rebar, and filled with concrete. The forms are insulated on the inside and the outside, providing high level of wall insulation uncommon in standard home construction. Because the ICF blocks fit together virtually seamlessly, and filled with concrete there is almost no air infiltration, increasing the effective insulation value.

The forms we used to build our house consisted of two layers of insulating foam approximately 2 inches thick, inside and out. The rigid insulation sandwiches a 6 inch thick layer of concrete.

The Insulated Concrete Blocks measure roughly 16 inches tall by four feet long by 12 inches wide. They have an inner and outer plastic framework in the forms that stabilizes the form and provides strips that can be drilled into to mount drywall, cabinets, wood trim, and siding on the outside.

ICF can be used for basements, underground homes or entire multi-story homes. They can start at the foundation and go all the way to the roofline, as in our construction. Some builders use only insulated concrete foundation forms and combine them with other building methods above ground.

ICF Energy Efficiency

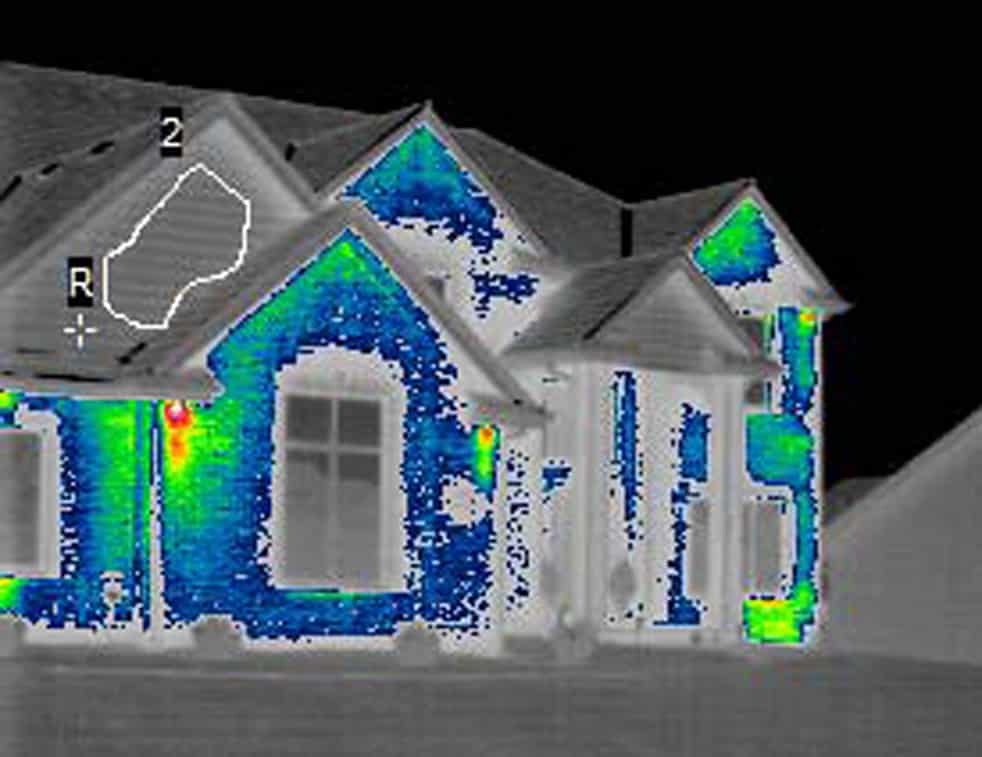

One of the primary reasons we chose Insulated Concrete Form construction was for its energy efficiency. Because the walls are uniformly insulated with a solid sheet of foam inside and out, there are no channels for air to seep through.

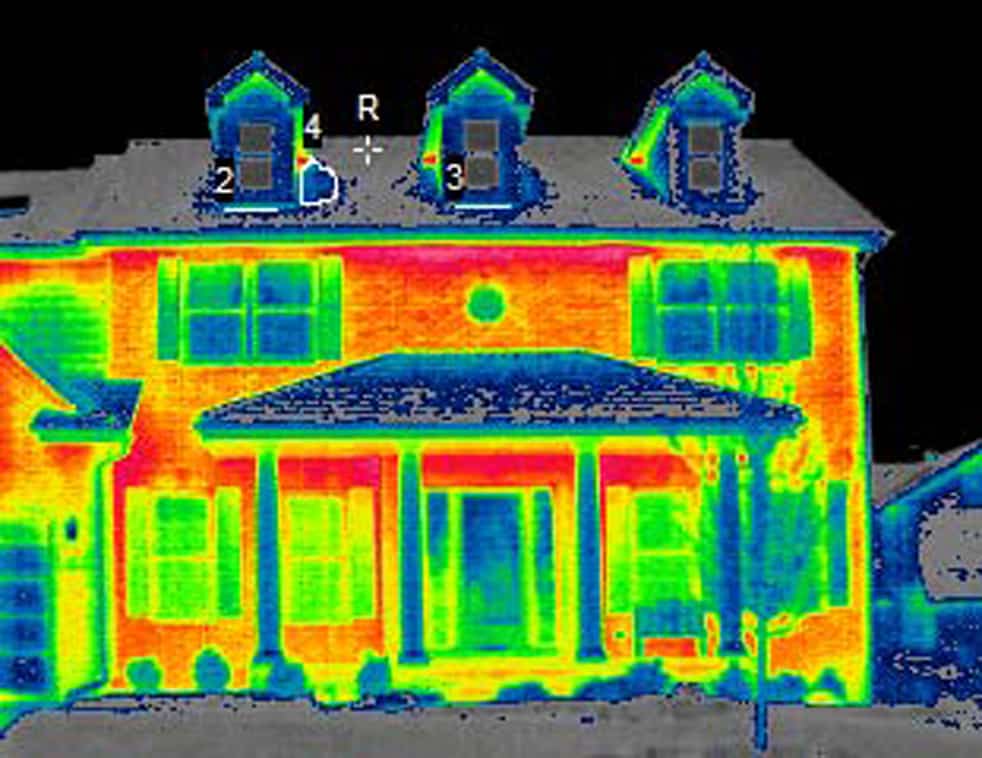

You will not find hot and cold spots on an ICF wall. In stick built construction, your effective r-value is greatly diminished by air infiltration and heat transfer along wooden studs and around outlets and other wall penetrations where the fiberglass insulation does not fill the area completely (spray foam insulation is better, but you still have heat transfer along the studs).

Thermal images courtesy of Reward Wall Systems.

The amount of concrete used in the structure gives the home high thermal mass. This means that is holds temperature very well. Heat it up, and it stays warm – you don’t lose heat to the surroundings.

Fill the house with cool night air in the summer and close it up during the day, and it stays cool. Windows at the east and west ends of the home allow us to take advantage of winds off Lake Michigan to flush warm air out of the home.

“Homes built with ICF walls require about 44% less energy to heat and 32% less energy to cool than a comparable wood-frame house, based on a study of 58 single-family homes located throughout the U.S. and Canada.” ConcreteNetwork.com

Our Experience with Heating and Cooling

When I ran the numbers on our home, our energy use rates (heating, AC and electricity) placed us in the top 5% of homes in the US is terms of efficiency for square footage. These are my own rough estimates based on utility bills and wood use. My best estimate is that in an average year we get 10% of our heat from passive solar, 40% from wood and 50% from propane via our in floor radiant heating system.

We were able to provide all our hot water and heat over 3000 sq.ft. of living space with a 46 gallon Combi-Cor water heater. A Combi-Cor heater is a water heater with built in heat exchanger for space heating. In 2013 our Combi-Cor died. We replaced the Combi-Cor water heater with a boiler system because it has a longer estimated lifespan.

Windows are placed to maximize cross ventilation when weather permits. The house is exceptionally airtight, so we also installed a Fantech HRV (Heat Recovery Ventilator). An HRV brings outdoor air inside and preheats it with stale indoor air before it enters the home – fresh air in, stale air out.

The HRV could also be fitted with specialized filters to address toxic air problems outside the home. During extremely humid weather, we do have some minor condensation/mildew in the basement if I don’t keep the air moving. In floor radiant heating eliminates this in the winter.

ICF Durability

Another reason we chose ICF construction is the durability. When we were building, I read a story about a Florida couple who had built an ICF home for hurricane protection. One night while they were sleeping, they heard a thud outside their bedroom. When they went outside to have a look, they found a truck had run into their home.

The truck was a complete loss; the home only had a few hundred dollars of minor damage. With six to eight inches of concrete, most standard ammunition will be stopped. Insulated concrete forms also offer protection from many other concerns, such as the following.

Storms, Tornadoes and Hurricanes

A quick google search of “ICF hurricane proof” or “ICF tornado resistant” will yield dozens of images of ICF homes left intact in area where the surrounding homes have been leveled.

“Around 1 am on August 7, 2013, a tornado touched down within 5 miles of our home. Inside our ICF home, the storm sounded very much the same as a typical thunderstorm, although I did note that the thunder had an odd tone to it – that low “freight train” rumble you hear people talk about. The warning sirens never went off, and we stayed in bed. I had no idea there was a tornado nearby until the next day. There was no damage to the house at all, but it’s a disconcerting feeling to know that the funnel hit so close without us realizing it. I think the weather radio needs to live in the master bedroom.” – ICF Owner Note

Fire

While the contents of the home are still flammable, concrete itself is not. You have no chance of an electrical fire being concealed inside a concrete wall.

Radiation

Concrete can stop all kinds of radiation, including alpha, beta and gamma rays. There’s a reason that nuclear containment vessels are built out of concrete.

Pest Protection

ICF construction is also much more pest resistant – nothing eats or can chew its way in through concrete. Termites and rodents can use the foam for nest material, so in termite prone areas, pre-treated forms should be used, and sealing near ground and around windows and doors is important.

Seismic Activity

With additional reinforcement appropriate to the level of seismic activity in your area, ICF construction is highly resistant to earthquakes and other shifts.

ICF Cost

At the time that we built, our builder estimated that ICF homes cost about 6% more than stick built. Part of this is the cost of the materials themselves, part of the cost is additional labor involved in working with some aspects of ICF. This is likely to vary over time as material costs fluctuate. Some ICF manufacturers offer discounts on forms to those who are rebuilding homes destroyed by storms in officially declared Federal disaster areas.

As for finding a builder who was familiar with ICF, that was a little tough. At the time that we built, it was a newer technology. Now that its benefits become better known, it’s becoming more widely used, especially in areas that are prone to tornadoes or hurricanes (more on that in a bit). There was no difficulty in obtaining financing or special permitting required, as the use of ICFs is an approved building method.

ICF Construction

As mentioned at the start of the post, the concrete forms are assembled, Lego-style, laced with rebar, and then filled with concrete. Because the concrete and rebar provide the strength of the wall – not the form – temporary framing is used during the pour. Our home uses these forms from the foundation to the roofline. Other options are basement/foundation only, or for building/retrofitting a safe room within the shell of a home.

Would you like to save this?

A wall is framed out with the ICF forms, V-buck openings, and bracing, and then poured in “lifts”. Rebar is set inside the forms and tied. Windows and doors are framed using “bucks” (box outs that create a frame for a window to fit inside.

A “lift” is about three forms high. They fill a wall about three forms high with concrete, let it set, and then fill another three forms in height, and so on. If you attempted to pour the full height of the wall in one pour a blowout would be likely. Because of the need to use lifts, the concrete pumper truck must visit multiple times (once per lift). The multiple concrete pump truck visits are a big part of the cost, along with the rebar labor. (It’s a lot tougher to lace rebar through walls than to just lay it in a flat slab.)

Layers are added until a “floor” height is reached and a header/hanger is added to support inside trusses. In the case of the roofline, hurricane ties are added for the roof trusses.

Plumbing and Electrical in ICF Construction

Plumbing and electrical must be done a little differently than with a stick built home. It’s much easier to plan any wall perforations in advance than to cut them after the fact. Electrical wiring on exterior walls is done by cutting into the insulation, laying the wire, and then sealing the cut with spray foam insulation and trimming flush.

Plumbing on the exterior walls can be done in the same way, but is generally avoided. Inside, the framing, trusses, etc, are the same as in a conventional home, although we did use open trusses to facilitate the installation of ductwork and radiant heating coils under the floor.

Finishing an ICF Home

Drywall is screwed into plastic strips in the ICF forms, allowing the home to be plastered and finished like a conventional home. There are no ugly, bare concrete walls. The only indication you have from inside that the house is not standard construction are the deep window wells and doorways.

The look and functionality of the home is similar to a standard home, only better. (I may be biased. ;-)) The interior and exterior can be finished in the same way as a conventional home – siding, brick, drywall, paint, carpets, etc. In our case, we chose to use all hard surface flooring on the main floor and acid stained concrete in the basement to maximize the heat transfer from the in floor radiant heating and improve indoor air quality. Our home is certified Wisconsin Green Built and Energy Star compliant.

We utilized no and low-VOC materials and finishes within the home; sustainably harvested hickory and wheat board for our cabinets and shelving; green flooring such as tile, cork and linoleum – I could go on, but you get the idea. About the only thing that is a little tricky is hanging things on the exterior walls, because there are no studs and the stripping is hard to find under the paint and drywall. I use removable adhesive tabs instead.

Do it Yourself ICF Construction

I would not recommend do it yourself ICF construction for the average handy person. It can be done, but you need special equipment and you don’t want to screw up. Walls and openings must be well braced to maintain structural integrity.

You only get one chance to pour it right and it can’t be adjusted after the fact. Dedicated ICF builders have specialized braces for this purpose, and know how to work with the forms to avoid problems. Also, the cement mix must have just the right consistency. Too loose, and you risk blowing out a wall. Too thick, and you’ll end up with air pockets in the wall because the cement has trouble filling the forms completely.

If you are on an extremely tight budget, and ICF safe room is probably a better choice. A safe room is a small, windowless room built inside the shell of the home or garage or nearby, that is used primarily for emergency shelter.

Our Experience Living in an ICF Home

The home is very quiet. The noise reduction from the ICF is noticeable to anyone who visits. We’ve been in the house over 15 years now, and it’s holding up extremely well. Several people who came to last year’s open house noted that the home didn’t look 12 years old.

Our heating and cooling bills are still low, and I would definitely recommend ICF construction.

ICF Recommendations

Our first home was a stick built, our second is ICF. After going through the building process with both, there are a few issues unique to ICF. (These may also apply to other specialized building options.)

Plan for Ventilation

You need plenty of ventilation because the home will be so tight. Don’t count on natural convection (normal heat/cold airflow) to move air around the house. You will need point source ventilation and an HRV or ERV with ICF construction.

Use an ICF Builder

Make sure you get a builder who has worked with ICF before. It is not the same as a stick built home. Windows and doors must be exact – you can’t cut a wall and add a stud like you can with stick built.

Get Durable Windows & Sills

Windows and sills must tolerate wider temperature swings and condensation if you use insulating window covers. Make all window sills tile or other water resistant material. Since our home uses passive solar design, large windows are needed. These must be covered to provide insulation at night to avoid excess heat loss. Covered windows + tight home = condensation. We have wood window sills on north, east and west windows. We should have done tile.

If the entire area around the window sill was tile it could be cleaned more easily.

I apply a layer of insulating window plastic on the inside of the north windows at the beginning of the heating season. We will probably upgrade to the triple pane windows with argon fill on the north side of the house when we eventually replace the windows, probably with storm windows also. Our existing window frames are vinyl to reduce heat loss from the home and prevent rot.

Other Miscellaneous Thoughts regarding ICF

Seals & Gaps. Ensure you get good seals around ground level. We have had some issues where concrete didnt fill in entirely around a door frame and mice got in.

ICF Wall Penetration. Plan for any sort of vents, pipes, or penetrations need to be done up front, maybe even leave an extra 4″ and 6″ closed pipe in the wall in some spots for future use. Getting through all that concrete is a major challenge.

Airflow. We added ventilation. The natural airflow is almost non-existent. If we did it again we would add more ventilation.

More on Green Building

Learn more about green home building and sustainable living on the Green Home page. My husband and I are also working on a book detailing our building experience and offering guidance for building a “lifetime home”.

If you’d like to receive information on when the book is available or have any questions/concerns you’d like addressed, leave a comment below.

Other Related Links

Originally published in 2012, updated in 2024.

Did you write your book? I really appreciate all the above information! We will be building an ICF in the next few months.

Hi Deb.

We started, but haven’t been able to find enough hours in the day with August working full time at his main job, all the work here on the homestead, and online work. Hopefully still on the “someday” list, but I’m not sure when.

I hope your build goes smoothly.

I built my house out of ICF, about 25 years ago. I live just outside of Northfield, MN. About 5 years ago, over 24 F0 and F1 tornados went through this area. I was watching the news on the TV, in the living room. And an F1 went just over my neighbor’s house. Then took out about a 1/4 mile of wooded land. And it headed straight for my house.

Because of the construction of this house, I did not know this until the tornado was hitting my house. It then sounded like I was standing behind a big jet plane. After bouncing off of my house, it took out most of the trees in my back yard. Then pushed a lot of trees onto my pole barn. That needed a lot of work to fix the one side of the pole barn. Then the tornado lifted back up. As for the damage to my house, the vinyl house siding had lots of little holes in it. And there was one pane of one window that was broken. That’s it. I like this house.

Wow! Thank you for sharing your story.

I am late to the post, but the claim that concrete will stop radiation is true, but only to a point. Please research how much concrete you need to have for a fallout shelter.

To clarify, a typical ICF home is not a fallout shelter, but will offer some protection from radiation.

Fallout shelter walls below grade should be at least 10 inches thick. Above ground, 1 to 3 feet thick concrete is suggested for actual blast/fallout shelters.

Do you think ICF is an owner/builder friendly product? Our client asked us to engineer an ICF house. It was a frustrating process – as much because the client was still learning about how to build, but more so because the engineering design tools just aren’t as polished as they should be (yet).`

If someone already has quite a bit of experience building, they may be able to manage it. For most people, I’d highly recommend working with a builder who has experience building with ICF forms, as their are some unique challenges to using them.

Hello! We are right no building an ICF home in Salmon, Idaho. Your blog has been most helpful in answering some of my questions. We have a wonderful Contractor who is very experienced with this type of build.

With the risng cost of wood we made out pretty good by going with ICF. After reading all of this I am so happy we did!

Thanks again for all of your time and the effort you have put into this blog….wonderful!!

You’re welcome, and I hope your home building goes smoothly.

Hello. We are looking forward to disseminating this technology of construction in our country, Libya. We suffer from extreme heat in the summer and extreme cold in winter, due to the poor techniques used in construction, which lack insulation.

How doe you run electrical wire through the walls in ICF construction

They run electrical and plumbing by cutting channels into the interior foam along the strips that provide anchoring. After the electrical and plumbing is in place, they foam over the top and trim it flat.

We are considering purchasing an ICF home mid construction. The property has been sitting unfinished for about 9 months. The person building was out of state and the house was started just as Covid hit. He couldn’t travel back and fourth and his contractor was not able to complete the project. I think they ran out of money. Roof is on and some window’s are in. Still needs the big sliders for the bedroom and family room. Rough plumbing and air conditioning ducts are in. The property has been open to the elements. Located in South Florida. Would the open exposure damage the ICF foam? It is on a canal which is my husbands dream and very hard to come by now. Anything else we should think about before saying yay or nay?

Please respond soon if possible as we need to make a decision soon.

Hi Carol.

The weather (rain or snow) isn’t an issue with exposed ICF forms, but UV radiation exposure can start to break down the forms and weaken them over time. Since you are in a high sun area, this would likely be more of a concern than here in Wisconsin. The references I found suggested that ICF not be left uncovered for more than three months, but if there’s shade or overhang, it may not be a problem.

Before you make such a big investment, I’d made a smaller investment in having a full home inspection done to look for any problems due to the house sitting unfinished, as I suspect it’s being sold “as is”. If someone who is familiar with the wear and tear homes take in your area gives it a thumbs up, you should have peace of mind for purchasing your dream home.

This is an edit. The property was open to the elements but the roof was put on as scheduled so the structure / foundation was completed as planned. It appears

they stopped after air conditioning duct work and rough pluming was put in.

Even with the roof on, the sun still shines at an angle on the side of the building. That’s where your UV damage, if any, would show up.

I don’t know if you have wooden subfloor, or concrete floors, but anywhere there’s an opening in the exterior shell, materials around that opening should be thoroughly inspected for damage.

There is a Quad Lock distributor in Sonora, Mexico.

is your product known or used in Mexico?

It’s not widely used, but searching “ICF construction Mexico” does bring up results with different companies who build with Insulated Concrete Forms, and homes in Mexico that have withstood hurricanes due to ICF construction.

I am in Milledgeville Ga. I have about 100 Amvic forms I need to get rid of. No corners.

Call 478-456-2267.

I built an ICF house in 2008. This was the first house I ever built and it turned out great

Good day, I’m interested to know if you used ICF for the basement as well, and if so, what moisture barrier you used.

Also, now that we are 8 years past your 12 year mark, is there anything else you would have done differently?

Yes, we have ICF from the basement to the roofline. The only part that is stick framed is the peaks at each end of the house.

To the best of my recollection, the only covering of the exterior of the ICF below grade is the dimpled black plastic moisture barrier. I sorted back through photos and didn’t find evidence of anything else.

We built in 2004-2005, so we’re at about 15 years now. It’s still performing well. Thankfully nothing new has popped up that would be an issue.

Thank you for that information! It was a pleasure reading through this and finding out all you did for your home’s longevity.

I lived in GUAM, HOW can I buy the ICF BLOCKS. MY GARAGE SIZE IS 24FT. BY 40FT. And what’s the cost?

I don’t sell ICF forms. You would need to contact an ICF distributor. Search on “ICF distributor Guam”.

Laurie, I’m in the planning stage of a new [probably] owner-builder home in southern CA. Why does every article I read about cost comparisons refers to cost per SqFt, not cost per linear foot? Are they referring to walls width x height, or SqFt area of home?

My home will have about 373 linear feet of 10ft high exterior walls, including garage. I priced (retail) 2×6 Fir @ 24″OC @ $2,110, using Rockwool R30 insulation @ $4,935; total $8,045 (no tax, no labor, no allowance for doors, windows, cement pumper, standing time, bracing, etc.).

I priced ICF 4″ thick STRAIGHT blocks ONLY with rebar and concrete @ $25,375 (using single-block price). So, materials only, that’s a $17,330 difference.

Even if I round the stick-build up and the ICF-built down, there doesn’t seem to be any favorable comparison. Yes, that’s about 4 1/2% of a $375,000 finished home, but in dollars, quite significant.

In a different scenario, anyone finding a way to shave $17k off their construction costs would jump at it. I’m expecting to be 100% solar and all-electric (with batteries and generator backup), so my utility costs should be near zero, even in a stick-built home.

My questions to you are (1) Do my numbers seem remotely correct?, and (2) what costs have I not considered which would add to or subtract from either way of building? For example, does it take longer to build ICF walls vs wood framed? Is the hourly labor cost higher for ICF vs wood framed (higher skill level required), etc.? Thanks.

Everyone refers to cost per SqFt because they are talking sqft area of the home.

ICF will cost more to build. I haven’t done a current cost estimate because we are not building right now, but in addition to the wall costs, the finishing costs also tend to be higher because sub-contractors have to work differently with ICF than stick built. If I remember correctly, our build estimated costs would be about 6-10% higher than stick built.

Where you make up the money is in operational costs, especially heating and cooling. ICF is also highly resistant to storm damage.

That said, if you don’t plan to stay in the house very long, it’s likely not worth the additional investment.

You must also have plywood sheathing over your studs to have an apples to apples construction comparison. Labor costs are more on stick built. ICF goes up , concrete poured, ready to go. Stick built is wall framing, sheathing, then insulation installation. Three processes for contractors. When we built our ICF in 2004-5, labor was the largest expense even though we did almost all the interior finishing and electric ourselves.

wonderful ICF home . planning to build one on large forested property . will have legalett slab on grade air heated floor with outdoor boiler gas/wood furnace . I may go for a second floor for added south facing fiberglass 3 ply laminated storm windows . We get micro burst now and again . Will go for HD steel doors . icf garage . Fully off grid system with propane generator(s) . wood cook stove for winter and propane for summer . same size windows , etc… Just too much to put in a comment .

Best regards and enjoy your home .

C. Bruyère

I hope your build goes smoothly. We get a lot of wind in our area, and the ICF is a blessing.

What is the cost for a 1800 sq ft house plan and a 3 car garage

You’d need to work with a builder and specific design plans for a specific location to get an accurate quote. We do not build houses.

I’ve been thinking…(i’m still learning) for passive air movement couldn’t you do the same as they do in Earthships? ( which is to run a 12-14in. tube underground capped for air flow at one end and run the other end to the house with a mesh screen to stop bugs form entering. this would be air conditioning system.) and if not couldn’t you just run a dehumidifier in the basement or main floor? I don’t think a fan would be enough. You want to get rid of the moisture not move it around right? This was a really great article along with great questions and replies. But I agree the home NEEDS to breathe somehow. which makes me wonder if gaps need to be strategically placed for air flow if nothing else leave a couple windows cracked . Nobody has talked about Carbon Monoxide poisoning. or stale air. I couldn’t imagine a teenage boy’s room.(gym locker smell that wont leave.) Or the off gassing of a pet in need of an overdue bath. LOL Eventually the home will need to air out somehow.

there are good design elements in the Earthship, Strawbale and IFC/CBS builds now if I could only figure out a way to incorporate them and the county to exept them .LOL Oh well back to my research.

In most areas, there would likely be some bickering with building inspectors on non-conventional HVAC elements. A local friend tried the tube option in her earth sheltered greenhouse, and found it performed well under expectations. Another friend tried to use it for cooling in Tennessee, and found that it offered little relief. Both of these were owner installs, so there may be design or installation errors, but they tried to implement as best as they were able.

We have a lot of windows place for good cross ventilation, so as the weather allows, we open up. We also have ceiling fans in almost every room for spot air movement, and HRV (heat recovery ventilator) for indoor/outdoor air exchange without heat loss in winter. We have forced air heating, and sometimes fire up the dehumidifier in the basement when moisture levels run high. (We were running it recently with the record setting rains.

CO sources are largely isolated from the living areas, and detectors are in place.

I’m planning on building a house in the north Texas area, known as “tornado alley”. I’m looking for any feedback from anyone having any positive or negative experiences if ICF construction in that area. Additionally, I’m told the clay soil in my area will prevent me from putting in a basement because if shifting. any suggestions?

There are a couple reasons why people don’t put in basements in Texas. Cost is the primary, but water table, clay contraction and expansion and generally higher frost line are all reasons. If you can afford a basement and don’t have clay (google “map clay soil Texas”) if you are in a high clay area, probably best to avoid unless you want to bring in soil or create some sort of buffer for contraction/expansion. I strongly recommend 4ft+ roof overhangs. Even in Wisconsin our overhang cuts our summer heat load (shading the home and not dumping heat into the house envelope) plus it reduces wear and tear on siding. Talk with the builder about doing hurricane ties embedded in the ICF for the roof. It will give the home (roof) even more strength. You will want good ventilation (a bit more than a normal home) because of how tight the ICF is. Also the home will heat and cool slowly (long swings) so you will want to think about that for heating and cooling. If you let it get too warm in daytime it might not recover overnight like a stick built. We have been very happy with our ICF home.

What kind of siding did you use over the exteriors of your ICF home? Recommendations?

We opted for a Dutch lap profile vinyl siding due to cost. It’s sturdier than standard vinyl siding, and the style we chose has a slight pattern to it, which helps conceal the high levels of dust we get out here.

Metal siding or brick are also good options, but note that brick requires special ICF forms at ground level for support due to the weight. I don’t recommend Hardi-plank or other composite siding. Too much risk of moisture wicking in from edges and trashing the siding.

I’ve wanted to add onto our existing poly steel home but can’t find anything on how much it may cost or if it is even possible. Any suggestions or info?

A competent ICF builder shouldn’t have an issue with adding on to an existing home, assuming there is room to do so and the foundation can be tied in properly. It’ll be more work than adding on to a stick built house, but they cut through the walls and tie the old and new together, just like any addition.

Costs will vary by area and scope of project.

Laurie thank you so much for this article. I had read it back in 2015 when my husband and I were planning to buy a new home. We came across your article and decided that it would be best to build a new home from scratch. The problem was that for the longest time we couldn’t find any ICF installers in our area. We almost starting building an upgraded stick built home but last year we found a company that helped us get back on track. I can truly say that I look forward to moving into the home when it is all finished. I’ll keep everyone posted. for anyone in Massachusetts I can recommend Daniel and Arthur from http://bluegreenbuildingconcepts.com/ They have been great with us since the beginning and really seemed to listen to our biggest concerns early on.

Can one assume that an ICF type home would be perfect on the East Coast of South Florida close to the beach? What type of foundation process would work best?

Were thinking of Building A home about a 1/4 mile from the Ocean.

ICF has been successfully used in hurricane prone areas, including Florida, for some time. As for the foundation, I’d suggest working with a local builder to design something appropriate for conditions. I’m not familiar with water table levels and underlying geology in that area.

I have two questions. I’ve seen ICF work great up North. I now live in very humid Charleston, SC. Do ICF homes have any issues with mold or dampness in the very humid South? Also, considering I live in a hurricane prone area, are there better options than a truss roof i.e. a concrete roof to match the stability of the walls. Thanks.

Excerpt from the article MOISTURE AND ICFS: THE FACTS:

From the article STORM-PROOF ROOFING in The Insulated Concrete Forms magazine:

Another alternative for storm safety is a safe room within the house. For instance, our roof does have hurricane ties, but we also have a concrete walled root cellar with concrete ceiling in case of truly severe weather. You can learn more about safe rooms here.

This is interesting…many are paying more per square foot for a stick built home than GA ICF’s builder quoted for an ICF home:

https://budgeting.thenest.com/estimate-home-building-cost-per-square-foot-25885.html

The stick built price quote per square foot seemed low, but pricing may be different in your area.

To GA ICF Dilemma,

We are looking to do the same as you. We have not hired anyone yet, but I have communicated with Dan of http://concretehomesga.com/ who said that most of their projects were coming in at $130.00 to $ 140.00 per sq. foot and that the the final cost of the project will depend on the individual plan and finishes chosen.

Our feeling is that less space than we might ideally want, whether we use this builder or another, would be worth it, to have the long-term savings. Right now, we pay on average $400 a month for electric and sewer, plus termite insurance and have had many costly issues with our stick-built home (we did not build this one). I would be interested in who you are talking with, since both of us are in the preliminary phase.

Hi Sarah.

Dan was is one of the ICF contractors I mention. He must be busy. I haven’t heard back from him in days. His general quote was around $125 sq/ft. What other contractor(s) have you been in touch with? They’re not easy to find in GA. Please share any information you may have. It’s been very limited. I would settle for CBS construction if I cannot find ICF contractors at this point. They are in either South Ga or Tennessee.

Not many in the Metro area. 🙁

What other issues are you dealing with in your stick built home? As stated above, I am renting a home and notice many things that are not to my liking. However, this is temporary. But moving forward, this is not the type of house I want to live in. Please feel free to share other contractors you found..

Thank you.

Hi there GA ICF Dilemma,

I haven’t chatted with Dan in a long while myself — hope he’s okay. I didn’t want to bother him again until I was sure we were ready to pull the trigger. Our issues with the stick built home are mostly resolved at this point but we don’t want to spend the rest of our lives maintaining a “regular” house IF we have the opportunity to build a virtually maintenance-free house. That is not a certainty yet but we hope for it in the future. The main issue with this house was that it was not properly weatherized which caused MAJOR issues several years in with water, carpenter ants, mold, etc. It’s taken a lot of work and money just to get it to the point we thought it was at when we purchased it and even then, “retro” weatherizing is never as good as doing it properly when a home is built. Regarding pros, I’m assuming you’ve looked here but in case you haven’t, it’s one more good resource: https://www.icfmag.com/

IF THE OWNER OF THIS BLOG IS WILLING, I WOULD SHARE MY EMAIL ADDRESS WITH YOU, BUT DON’T WANT TO POST IT PUBLICLY. LAURIE, thank you for the opportunity to converse here. If you are willing to get in touch with me privately via email, you could pass mine on to GA ICF Dilemma or send his to me, either way. Thank you.

Sarah – I’ll pass along your email to GA ICF Dilemma.

Thank you, Laurie.

You’re welcome.

Hello,

I am in North GA (Metro Atlanta area) and purchasing land at the moment. Having moved from FL, where we use CBS (concrete block structure) construction, I really dislike the feel of a stick home. I’m renting at the moment, and I can feel the air draft when temps drop, and the noise among many issues(landlord refused to seal the front entry and garage doors. I got new seals and did them myself). I am not used to the subpar quality construction I observe in GA. The common excuse is different wind rating stories (no hurricanes/Ex-Fla resident paranoia etc). But on the other end, I see that GA is also tornado prone. That had me thinking……

So it’s either CBS or ICF for me. I found two contractors, and one has been more interested in my future project. We have kept in touch over the past few months, sent me pics of his most recent projects and he offered to show me homes he built in the Metro Area. All good signs of a contractor that’s proud of his work. However his quote is $125/sq. ft. It’s far from the 3%-5% that local stick builders have quoted with the plans I showed them. The stick builders quoted between $72-$85 per sq. ft. That should put me between $75.6-$89.25 per square foot with the industry standard 5% increase of ICF over stick. Even at 10% extra per square foot, it should keep me below my max per square foot price. My calculated budget is at a max of $100 per sq. ft. My plan is for about 2500 square feet. And to reduce the cost, there are some things I am willing to do such as flooring, painting etc. (Things I think I should communicate with him moving forward). I don’t want to resort to owner builder at the moment and I don’t want to have to resort to either buying a local stick built home or dealing with the stick builders I also got in touch with. What am I to do?

My question is what was your per sq. ft. price for your home? I know it will vary from region to region, home plans and contractors. But don’t you think $125 is a bit much considering the plans are the same, and interior materials would be about the same? I don’t want to build a custom high end type home. Something fairly standard, with interior upgrades I will gradually update later on. I prefer a solid home over a good looking home that won’t stand a chance against the elements, and cost me more to heat and cool.

Another question, where can I negotiate to lower the per sq. footage price?

Unless you’re willing to become an owner/builder, odds are it will be tough to get your costs down beyond a certain point. Our builder told us up front to estimate that ICF would add around 10% over stick built, and I think we ended up a little higher than that because we had a number of custom features.

It’s not just the cost of the ICF walls. When the crews are working inside, ICF changes how electrical and plumbing are run and surfaces are finished. They cut channels through the foam to run wiring, and the wiring has to be attached to the forms differently than just stapling it to studs, and then the channels have to be refoamed and trimmed. You can’t put plumbing in exterior walls. When they are hanging drywall, they have to make sure they hit the anchor strips in the ICF. The cabinet guys had a bear of a time finding the anchor strips in the finished exterior walls.

Many contractors have a set team of contractors that they work with, and if you want to do those tasks instead, it cuts their team out of the loop and affects their bottom line. A good team works like a well oiled machine, and anything that changes that can cost them lost revenue on other jobs.

Sorry I don’t have a “magic bullet”, but I encourage to talk with contractors and see if any are willing to work with you on this.

Very interesting stuff!

We are looking into building an ICF home in the next few years for our retirement home. How do you find contractors who do this? I have been searching the internet but haven’t had much luck.

Thanks!

If you can’t find anything online, I’d try asking around and visiting home expos, if there are any in your area. In most communities, someone knows someone in the building trades who can get the job done.

I suggest asking ICF distributors for leads to contractors using their products in your area.

Hi there,

I’ve recently moved into an ICF house and have considered stripping back some of the poly on a small section of wall to expose the concrete on the inside.

Have you heard of anyone having success with this?

I guess the plastic ties will need to ground back and a lot will be dependent on the quality of the concrete pour etc

Thanks in advance!

Patrick

Why do you want to remove the insulation?

I built an ICF home in 2008. I was the contractor and I and one other person did all the ICF layup and bracing. I went to school for 3 days and had no problem with the construction. This was the first home I ever built.

I did my lifts 45 minutes apart and had no problem with blowouts. (One small blowout where a door opening was not properly reinforced.) I have been extremely happy with my home. During the pour I had several people watching the walls inside and out for blowouts.

Hi. May I know how can you repair an ICF wall ? For example one of the piece of ICF is broke, how do you change it ?

Hope to hear from you soon.

Regards,

Adrian

It depends on how it’s damaged. If something managed to damage the concrete, you repair the concrete, if the insulation is damaged you repair the insulation. When the walls are finished, it’s one solid unit of concrete laced with rebar. There are no longer individual blocks.

Hempcrete, anyone?

I have a icf basement with outside walls dry walled, my question is do I have to frame again to be able to finish my basement because of running plumbing and cable and what not?

You don’t necessarily need to frame. If a contractor is familiar with ICF they can cut into the drywall (and inside insulation) to create a channel. Our electricians used dull electric chain saws to cut into the insulation quickly to create channels then pushed in the cable and sealed the hole with spray foam insulation. The drywall would need to be patched and covered regardless, and you would lose a almost the stud space. The stud walls are a simpler solution.

Is the book available?

The one we’re working on? Not yet. Aiming for sometime in 2019. He works fulltime outside the home, and we spend a large amount of time during the growing season raising and preserving food, plus the website work, so it’s a challenge to carve out time.

Our family moved from GA to WI in late 2013. We were fortunate to stumble into buying one of the few ICF-constructed homes in our immediate area with our move. The home we bought in WI has 4119 sq. ft. of finished floor level with the finished main floor level of about 2700 sq. ft. and the remainder being finished basement. The 3-car attaché garage is also of ICF construction. This home was constructed as a Metropolitan Milwaukee Parade of Homes model in 2002. It has a single 60,000 BTU forced air furnace and one 3 ton AC unit. An air-to-air heat exchanger provides fresh air ventilation and humidity control. We have triple-glazed casement windows throughout and 24-inches of blown-in attic insulation. Our heating and air conditioning bills are about 60% of that for other homes in our subdivision despite the fact that our home is larger than most that I am comparing ours to. With ICF, we have great isolation from outdoor noises, have very few issues with insects and no issues with mice getting into our living space. For comfort and good humidity control, we keep our HVAC ventilation fan running full time. If we keep our garage doors closed except when leaving and returning, our garage does not freeze during cold winter months, even without space heating provided. We have very limited issues with winter humidity condensation on windows, even with the subzero days often affecting the area during winter months. With our good tight-fitting windows, we have no comfort issues with draftiness. ICF construction is clearly the way to go. I wish I had known about it sooner. If I had, I would have built my last two homes using this construction, it being well worth the extra cost in reduced energy consumption, security, quietness and comfort.

Interesting questions and answers. We build an ICF house in2001,moved in in 2002. In addition to the house we installed an underground heat pump system that worked great. It worked as a heat or cool bank system. After the cooling season the water in the underground pipes would heat up to about 80 degrees, and we would start heating the house in the fall from that level, and when spring had come the water was cooled to about 36 degrees and we started cooling from the underground system with that degree. We had a walk-out down stairs and never had a mold problem. There is one huge regret we have about the house–we sold it after 14 years and moved to Texas.

Where was your ICF located, in a more arid or more humid climate? We have a high water table here, so I’m sure that plays a role in the basement being prone to dampness.

I Have Two Home one made out of ICF and the other made out sticks. I cannot believe the Quality difference ones strong and temperature stable! The icf home in fact survived a hurricane with minor only flashing damage at the roof line. Funny! I slept through the storm! On the other hand the stick built home is Noisy and drafty and not so stable. My wife calls the stick home A piece of you know what..She love her ICF home best. I was lucky the ICF home cost less for some reason..operational cost are 30% less…and the stick built home rated somewhere around 70 on the HERS rating..

Thanks for sharing your experience. I know the subcontractors around here aren’t used to working with many ICF homes, so I’m sure that was part of extra costs.

Hi, I was wondering about ICF homes in Florida. Their are advantages to this type of building for storms but the mold issue could be a problem in that climate. Could you please outline the building features that could be added to make it a more resistant build to mold. Also could you list the types/brands of forms out their for contractors to use for construction. Are their any forms that use 4 inches of concrete.

lastly if going below grade in Florida what are the costs of additional below grade construction features.

Thanks Bob’s Contracting Services.

im from michigan.

Yes mold is definitely an issue with ICF or SIP (and any other very tight building). You need extra airflow (full size house fan with vents in all areas) and a air to air heat exchanger HRV/ERV is absolutely necessary (for southern homes the humidity would drive me toward recommending the ERV). As to the brand of forms, we don’t have a recommendation. And you would have to contact local Florida permitting agencies (and a general contractor) to get costs and details for below grade construction. We live in Wisconsin.

I am probably going to build but with AAC. Thanks for the tips on the windows. However, George Swanson, a guru of environmentally safe homes, doesn’t like icf because he has found mold or bacterial overgrowth in the concrete due to the fact the foam is not breathable. Walls need to be waterproof but breathable. Anyway, we just tripped on a poured concrete house like yours w icf and do like it. Wondering whether its safe for us to buy and not build our own. I don’t like the icf for lack of breath ability. Concrete definitely can get other organisms besides mold. However the house seems utterly mold free (I’m sensitive and always react). Will do a voc analysis anyway. My bigger concern and chagrin is that his subcontractors insisted on wrapping the whole structure in tyvek. We are in Georgia. I guess they don’t understand concrete homes. He protested but they said sorry that’s code. Tyvek stops breathing at all after a few years. Tyvek is a bad deal. Do you have any thoughts about longterm consequences and how I can estimate potential issues? I will go look at your links. My building consultant agrees its a drag the house is now not breathable but thinks a really good redo of hvac with hepa and ERVS would mostly protect us, add another 10k to cost for me tho.

If you choose to buy it, I’d definitely opt for the HEPA and ERV. I think it’s crazy that they had to tyvek the house for code. Our house has been fine for nearly a decade – until this year. We had a record setting winter last year in terms of snow and cold; a cold, wet spring, and a wet, cool fall – really wet – but not really cold enough to turn on the heat. We had a sudden bloom of mold and mildew growth in some areas of the basement that I’ve been working to completely eliminate since.

Yeah, I tend to think the subs were just stupid and used to conventional houses–and if he’d insisted they stop right then, he could’ve gotten approval from the county. I really can’t imagine it’s code to use tyvek on poured concrete–and I’m going to call *my* county where I bought property to be sure I don’t run into the same problem.

Definitely will do an ERV and hepa–have a redesign of the hvac by my guy.

Basements are notorious–soil has so much moisture. They originally were root cellars that people lived in while they set up a garden, got animals, got to know their land, and then built a house (as far as I know.) I think basements are really a bad idea. Build out or up, not down into the moist dark soil. If I build, I’m going to pack sand before I lay a slab, and there are other things you can do to stop soil moisture from wicking up the concrete. But I am sure you’ll solve your problem. I’d get sick from that bloom.

I really do like the house…I’m sorely tempted, and I could use the new fannie mae 3% down and 3% interest that began on Dec 8, making my monthly cost very reasonable. But the house is overpriced for the area of course, on the assumption somebody will want it for the materials and construction.

Earth sheltering has been around for more than basements for a very long time because of the awesome protection from the elements – but it does come at a price. In our climate, basements are standard, and do offer living space that’s protected from the cold, which is really important for many months of the year. We do have a sand bed under our slab, and a moisture barrier, and heat in the floor itself – but it’s been record setting weather, and I tried to manage with natural ventilation when I should have used the HRV more. Live and learn.

We don’t spend much time in the room with the bloom – which is how it went unnoticed for a while – but I think with cleaning, ventilation and the space being heated for several more months, it’ll be okay.

We ran into bad luck in terms of when we built. It was during the boom years, so house prices were maxed out. Now we’d be lucky if we were able to sell for what we still owe.

I hope that whatever you end up doing, you get the house you need – and no mold!

My wife and I built a custom home in Ontario Canada where we have a four season climate! We chose ICF and built from the footings to the roof trusses! The house is 2,100 sq. ft on the main floor and 2.100sq. ft. Basement. The 2 acres we built on is all sand hence no drainage problems we put weeping tile around the footings which go to a sump pump in our basement which also collects condensate water from the boiler for our hydronic in floor basement heat and condensate from our gas fired furnace which rarely runs in the winter but runs in the summer for our air conditioning then we pump the water out to our flower gardens!

The contractor wrapped the basement with a heavy waterproof Dimple wrap to keep water away from and to protect the styrofoam and then parging was applied blending and finishing up to the brick ledge then we back filled with the same sand that we excavated for the basement! The house is stoned all the way up to the roof at the front and five feet up the wall on the other three sides with a sandstone ledge. Above the ledge we strapped the walls then put typar over the strapping then covered with vertical vinyl siding which gave an air space to avoid moisture!

We have been in the house 2 years with absolutely no condensate problems with the exeption of some condensation on the bottom of the windows on extremely cold days! Now I am in the process of installing our HRV unit in the basement which I am sure will solve that small problem!

Yes ICF does cost more than a house with a block or formed concrete basement and wood frame but the comfort and energy savings are significant! By code I was required to cover the internal basement walls with 1/2 ” drywall for a fire barrier and have had after 2 winters no mould or water problems that is why radiant heat is a must !

I have the thermostat in the basement on low during the summer to keep the system operating and keeps the floor comfortable as the basement cools down due to the AC ,this not costly but necessary as it is a living space used by Grandkids and friends! We are in farm country but close enough to have natural gas but all the same equipment I have will also convert to propane!

Thank you for sharing your experience, Dave.

Hi I am in Ontario as well thinking to have a full ICF but little worried about mold and windows installation as I have the max windows in the house building code has permitted and with 11 feet ceiling windows are 8feet tall

Any advise

Just make sure you have good air flow throughout the home. Ceiling fans and forced air ventilation keep things moving, an HRV or ERV can ventilate to the outside without losing all of your heat.

Hi everybody, thank you for sharing your experience with ICF. We live in Ontario and are in the process of revising our building permit, to switch to ICF. Dave, would you recommend your builder to us. Cheers, Michael

When the mold and mildew appeared was it ONLY in the basement or did you find it in other areas of the home? Would eliminating a basement make more sense when building this type of home?

It has shown up in the basement and on the windows when we use the cellular shades and condensation builds up on the window in the cold. I’d never build a home without a basement in our climate. After living in our home for ten years, I’d be very hesitant to build with ICF in a humid climate if I had mold sensitivity, because the house does not breathe well.

Create an Air exchange . Research, and talk to water engineer or air Quality Engineers. Traditional house have always been built on the breathable concept . The keep water out . Then there is the moisture barrier? Keeps Moisture out ? Gases ? Moisture is humidity. The air itself , unless you live in a dry desert environment? Moisture likes to rise from under ^ houses . Then escape through pores in walls and ceilings. Opening. . (A breathable stick frame ). For mold , there are new biodegradable material mold treatments. Research . Do not use (Bleach.) it forms gases . Peroxide will and and is used , to eradicate mold . Living plants are recomented . You can use artificial light when needed . Certain lights can also heat and kill secific molds . You need to research and think out of box . The only (single)solution is a (Mixture of solutions)! I choose Plants First ! Create an invironment for the plants to thrive in ! You will thrive with them . PS. If you lock yourself into only one solution? You won’t find away out .

We will start building a ICF house in June 2014. We have a experienced architect and builder. We live in Missouri where winters can be below zero and summers can be over 105 degrees. I know you are not a builder but I respect your opinion since you are already living in a ICF home. Our builder is guiding us to electric baseboard heating since the house will be so efficient with radiant floor heat in the basement–in your opinion will this be enough to heat a 2300 square foot house? Of course we will have a air conditioner. With the blower from the inside air conditioner unit will we need a heat recovery ventilator for air quality also? Also if you had to do it over again what do you wish you would of included in your home? Thanks in advance!!! Love your blog!

Yes, electric baseboard heat would most likely carry the load, but I’m not sure about lifetime costs versus installation costs. Around here our electric rates have gone up every single year we’ve lived here.

I haven’t lived outside of Wisconsin, but I suspect humidity might be your biggest challenge. If you don’t opt for an HRV or ERV, make sure that you have high quality spot ventilation in the bathrooms, kitchen and laundry. Placing the stove and dryer on outside walls to minimize the distance air needs to travel to get outside will increase efficiency.

If we were building again, I’d seriously consider a wood cook stove instead of the masonry stove, because it can do double duty more easily. We’ve been having some trouble with our masonry stove, and there is no one in the area who works with them. I’d also want to have the front of the garage more flush to the front of the house so our front door was more visible when people pulled up. Smaller windows would be a must. There was a miscommunication with the builder, and we ended up with larger windows than anticipated. They should be 7-8% of floor area, not close to 12%. We might shoot for sheet linoleum instead of plank linoleum (the seams are becoming more visible with age), but it wasn’t readily available when we built. I would have loved to be able to squeeze a standing seam metal roof into the budget. A bigger greenhouse and root cellar would be great, too. 😉

I’m living in an ICF house also and was very interested in your article, especially your comments about condensation. The one (big) problem I’ve had is with the windows. At first I had all aluminum storefront with a thermal break. The condensation in the winter was so bad I’d get up to 1/4″ of ice on the aluminum sills. I had all of them replaced with Aluminum Curtainwall which has a higher condensation resistance factor. I still have issues, especially at the beginning of the heating season.

These storefront and curtainwall systems are used throughout this area with no problems. The one difference I can see is my ICF construction. I don’t know why this is true. I’ve searched the internet for answers and haven’t found any.

On the up-side: My energy bills are very low and here in tornado country I’m happy for the extra protection.

Since the walls are largely impenetrable, the only thermal pathway left is through the windows. We choose vinyl windows because of this (lower thermal conductivity), with v-buck framing. All windows are covered with double honeycomb cellular shades at night and opened during the day. If there’s sun, the condensation will clear on the south side. With extended lack of sun, i wipe up condensation with an old towel. On the north and west sides, once it gets cold, I add an additional layer of clear plastic to the windows. I get some condensation, but not nearly as much – nothing more than a few drips, unless it gets bitterly cold.

Hi Laurie… Love all the info you provide on your website. I would love to share some of the articles with my followers on facebook … if you don’t mind? You have written extensively about root cellaring with photos! I do have one question… on the ICF walls for your home, isn’t the foam form like heavy duty styrofoam? And if so, what about during warm weather where styrofoam can gas off formaldehyde? Do you have any info on this?

As a Wisconsin Certified Green Built Home, part of the requirements our builder needed to meet was the use of low or no VOC materials. I don’t have the specs for the ICF close at hand, but I know that this was part of the certification. It did come up in discussion of other materials, such as the particleboard,cabinets and other insulation. There has never been the typical “new house smell” indicating outgassing of VOCs, even in the first summer when it was very hot and humid. Given the tightness of an ICF home, outgassing would be a real issue if it occurred, even without the additional Green Built certification.

Yes, you may share links to posts and post snippets, as long as credit is given.

Do you have a rough sketch of the plans you could post?

I’ll be posting more house information, including drawings, in upcoming articles.

On the mold comment ICFs actually help in reducing risks of mold. Remember what mold eats- organic material. Mold wont eat foam and mold won’t eat concrete. Mold could eat the drywall or the trim or the wall paper, but that’s the another great thing to ICF as well. Rip down the wall paper, remove the drywall, wash the foam wall behind it down and then replace with new drywall. Mold problems solved.

So remember kids mold needs something organic to eat and moisture to grow. ICFs remove the food source and don’t allow moisture penetrations through the wall (openings, flashing, transitions are the culprits)

Had any problems with mold? Love the idea of ICFs, but wonder about mold getting in between the forms and poured concrete . . .

No mold issues here, and that’s not something I’ve heard of being a problem with ICFs. If fact, ICFs are generally more resistant to mold than other types of construction. This article explains – http://www.polysteel.us/GreenGuide/PDF_files/tab7/03_Mold_Issues_with_ICF_Walls.pdf

Love this post! Very interesting. My uncle is a contractor and built one of these homes for himself (although he did not keep it). Will you be talking about how this compares to other unconventional homes? Such as straw-bale construction?

Sarah – not in these two posts, but perhaps at some point in the future, especially if I can get a straw bale person to weigh in. I prefer first hand experience when possible.

Contact Tate Locke Construction Cedar edge Colorado. Tate is a high end builder of efficient homes. He built and lived in a Straw Bale home he lived in for several years.