Rocket Mass Heaters: 10 Things You Need to Know

This post may contain affiliate links. Read my full disclosure here.

Rocket mass heaters can save money you money on heating costs, reduce your environmental impact, and keep you warm in the coldest winters.

When I first heard about rocket mass heaters I was kind of skeptical. I read that they could eliminate something like 80-90% of the wood of a conventional stove and I thought, “Bah! That seems like a pretty unreasonable claim to me.” So I put on my investigative pants and got pretty obsessed.

One of the first articles that I came across was Paul Wheaton’s article on rocket mass heaters. He does a good job of breaking down the technology in a way that anyone can understand. So, I am going to relay some of his information as well as some other details I scrounged up!

I want to tell you about several of the reasons why rocket mass heating is so important. Let’s jump in.

#1 – What is the difference between a rocket mass heater and a wood stove?

Rocket Mass Heaters are like masonry heaters, except that people are building them for a LOT less money. They are super efficient, and hold the heat much longer than a conventional wood stove.

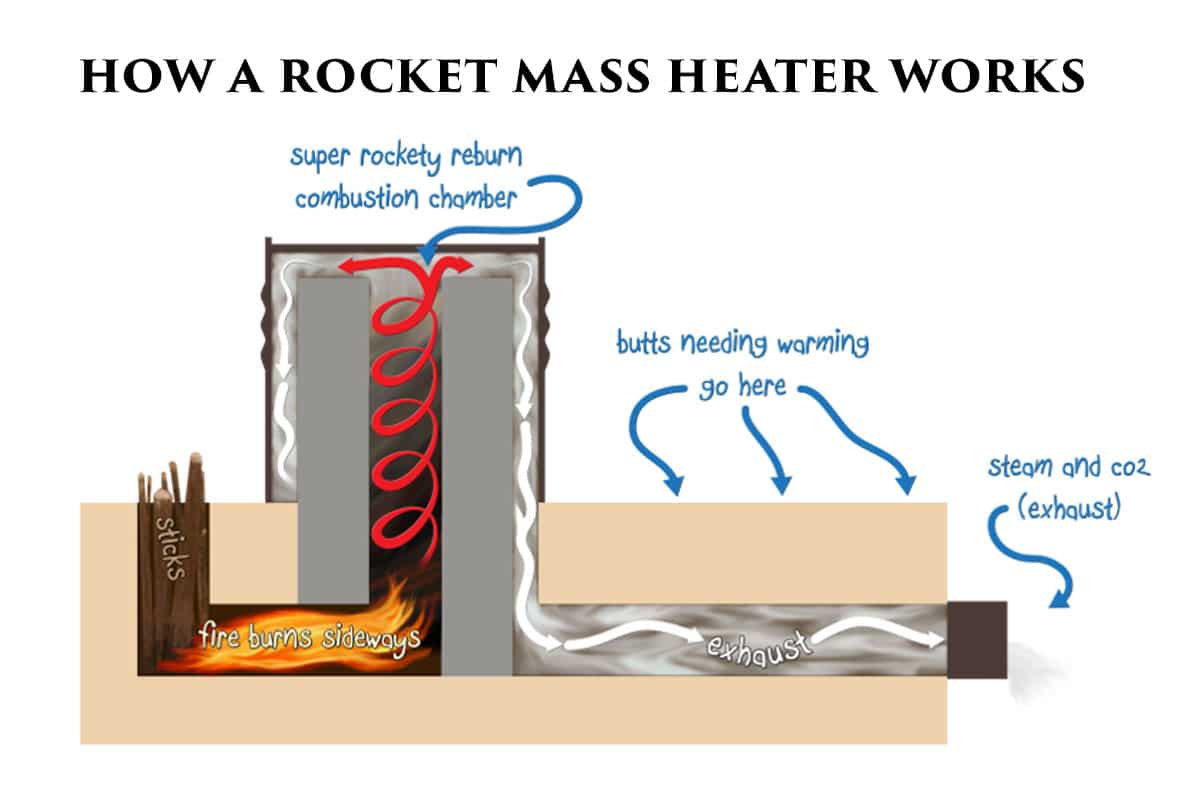

First, the sticks are put into the wood feed vertically. They are standing straight up. Then, only the bottoms of the sticks burn, and the fire burns sideways!

How does the fire burn sideways? The heat riser in the barrel is so insanely hot that it creates a convective current. This pulls the fire sideways into it.

Next, the thermosiphon draft pulls the smoke from the fire up into the riser and into the barrel. The sharp turn mixes that smoke with fire so it burns up the smoke in the secondary combustion chamber! Thus, it only leaves a tiny bit of CO2! It’s nearly purely steam. The image above illustrates this process.

#2 – How well do rocket stoves work?

Rocket stoves or heaters work exceptionally well. They are able to heat large areas while being very fuel efficient and clean burning. This makes them both economical and environmentally friendly ways to heat an interior space.

When the exhaust runs through the cob mass, the mass absorbs the extremely high heat. Then it slowly releases the heat over the course of a few days. This enables the rocket mass heaters to continue to provide heat for many hours after the fire has stopped.

This drastically reduces the amount of wood needed to sustain these bad boys. Some people heat their home using only dead yard debris and scrap wood, eliminating over $150/month in natural gas bills.

How much energy can rocket heaters put out?

The overall energy output can range drastically depending on the style and size. Some rocket mass heaters put out an equivalent of 250,000 BTUs.

How many square feet can a rocket mass heater heat?

Can a rocket mass heater heat your entire home? Probably! The max square footage rocket mass heaters can comfortably warm ranges from 800 square feet to 3000 square feet. The amount of heat depends on the type, size, and design of the unit.

What are the benefits of a rocket mass heater vs natural gas?

This one surprised me, because natural gas is supposed to burn really clean. I didn’t know wood COULD burn that clean. At high temperatures, wood burns down to steam and CO2, with a little bit of mineral ash left over.

Consider the environmental footprint of extracting natural gas (like fracking), refining, and the miles of pipes or delivery tanks that have to be in place for you to use it. By comparison, harvesting local wood looks pretty clean.

#3 – They are super comfy to sit on, like a full body heating pad.

Did you ever crouch over the heating vent in your nightie or pajamas, trying to get warm enough to get dressed? Good way to be late to school wasn’t it?

Moving hot air around is not an efficient way to heat things. Air doesn’t hold a lot of heat, plus it causes evaporation, which makes you colder. Forced-air heating is pretty inefficient. The reason it’s so common is that it’s relatively easy to control with thermostats and vents, and not as dangerous as steam heat.

These rocket mass heaters are more efficient like steam heat, but way less dangerous. The surface temperature is just warm to the touch. They are usually sculpted into heated seats or beds. If you need a warm-up boost, you just curl up and tuck your toes under the cushions.

Over-worked friends just kind of melt onto the bench when they come over for dinner.

#4 – Rocket mass heaters can be completely DIY.

These rocket mass heaters can most definitely be built by you and yourself alone. Ernie and Erica Wisner have taught tons and tons of workshops on how to build them. Respected teachers all over the world have, too!

This is not to say that is is 100% simple or fool proof. You definitely need to do your research and especially need to figure out which kind of rocket mass heater is best for your situation. However, with research and careful planning, you can definitely make one by yourself.

What is the best material for a rocket mass heater?

A big part of these rocket mass heaters being so efficient is the actual thermal “mass” part of them. There are several types of mass that have been experimented with, but the most common mass is made out of cob. (Cob is a natural building material made from sand, clay, water, some kind of fibrous or organic material (straw) and earth.)

#5 – You keep far more heat inside your house with a rocket mass heater than with a conventional wood stove.

A conventional wood stove uses a lot of the heat to push the smoke out of the house. With a rocket mass heater, the heat gets absorbed into the mass. This extracts as much heat as possible before the exhaust leaves the house.

Would you like to save this?

Can you burn a rocket stove indoors?

Yes, as long as your rocket stove has the proper venting. Large rocket mass heaters are designed specifically for indoor use to heat your whole house, tipi, or barn. Portable rocket heaters are typically not designed for indoor use. This brings us to…

Do rocket stoves need a chimney?

Rocket mass heaters or stoves must have an exhaust. This can be a chimney or pipe that creates the proper airflow and venting needed in the home.

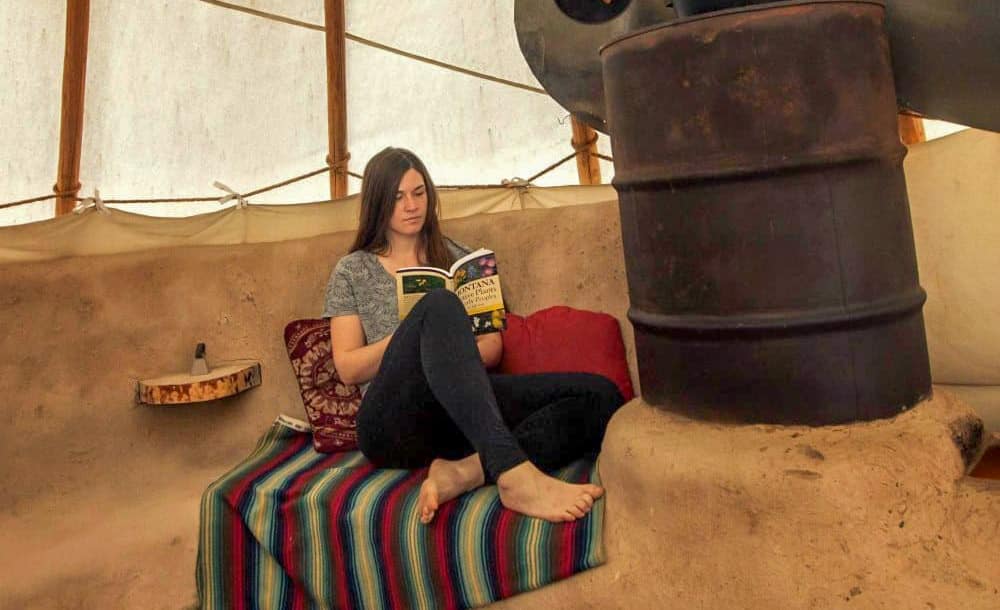

#6 – People are living comfortably in a rocket mass heated tipi through Montana winters.

Like I said, up at Paul Wheaton’s land there is a ton of experimentation going on. One of the coolest rocket mass heater innovations he has is the one that is inside of the tipi. It is a traditional cob style rocket mass heater that heats a completely uninsulated canvas tipi.

Each of the people that have lived in it have reported utmost comfortability. This is huge because Montana gets down to -25 degrees Fahrenheit in the winter. I actually visited Paul’s land in December and got to hang out in the tipi. It was completely warm and toasty in there!

#7 – Rocket mass heaters use old technology with a new twist.

This taps into what I was saying earlier about the heat getting absorbed into the mass. What it does is mix modern science with knowledge from hundreds of years ago. We burn the smoke and capture heat from the exhaust, while focusing on utilizing the more efficient forms of heat. Radiant and conductive heat are favored over convective heat.

The new twist is using modern materials to make the building process cheaper and easier. We also make the heaters more effective at getting the heat where people want it. The heat is right where they can sit on it and tuck their cold toes under the cushions.

- Convection is heat exchange via moving air or water, which is how most of our standard heating systems work.

- Conduction happens when two surfaces touch each other – such as your body sitting on the warm stove exhaust.

- Radiant heat transfer happens when warmth radiates from a hot surface to strike another surface. It doesn’t require air movement. Examples include warmth radiating from a fire or from the sun.

#8 – There are many different kinds of rocket mass heaters.

The most popular design for a rocket mass heater is a 6” Annex Variation, but there are many different options. Here are a few:

- Daybed Bypass Variation

- Bonny Convection Bench Variation

- Batchbox Variation

- Cob Style

- Pebble Style

- Wood box Style Shippable Cores

- Small Molded Shippable Cores

- Rocket Mass Heater that doubles as a BBQ, cooker, and smoker

- Rocket Stove with a griddle, oven, and hot water

- Batch Box Variation with heat directed into the floor

Portable Rocket Wood Stoves vs Built-in Rocket Mass Heaters for Home

Portable rocket wood stoves are used for camping or just being warm while outside on your homestead. The overall concept is similar to that of a rocket mass heater – burn hot and fast, and trap heat in the mass.

Rocket mass heaters are designed to warm larger areas for a longer period of time, due to their larger size and mass. Portable rocket wood stoves are much smaller, so they don’t hold as much heat.

See the Ecozoom Rocket Stove Review for more information on portable rocket stoves.

#9 – How much do Rocket Mass Heaters Cost to Build

The cost for these heaters varies greatly. DIY options can be anywhere from $50-1,000 to build yourself, while hiring a contractor can cost upwards of $5,000 in some cases.

#10 – What are the disadvantages of rocket stoves?

Some people may not love the large size of these stoves and the look of the mass used to retain the stove’s heat. The DIY models definitely have a more rustic look that’s not a fit for every home.

You also need a solid foundation, as the mass of the stove is heavy.

Final Thoughts

Rocket mass heaters provide a multitude of opportunities for heating your home in a clean, efficient, cheap way. They create a uniquely comfortable living area, and use local fuel.

To get a quick look at how a rocket mass heater works and “meet” Paul, Ernie, and Erica, you can watch the video below.

You may also enjoy:

5 Things You Need to Know Before You Buy a Wood Burning Stove

Cassie Langstraat grew up under the big blue skies of Montana. She has a fire in her soul for all things regarding literature, permaculture, and feminism. When she isn’t writing or poking around in her garden, she enjoys reading philosophical novels, fishing in the dark, and eating cheeses with names she can’t pronounce.

Originally posted in 2015, last updated in 2023.

I would like to know if the combustion portion of a RMH can be built on the outside of a building and the heat sync portion on the inside of the building. I have not seen any of these split installations. If the designs are out there can you please direct me to them.

You’d lose a lot of heat with that setup. I have not seen any installations like you describe.

Hi Jeff, Matt Walker created the Walker Boiler for hydronic heating with the rocket portion outside of the house. You can watch a video at Youtube:

https://www.youtube.com/watch?v=7XsK08XuT10

You did not explain one of the crucial features of the rocket stove in your illustration, without which it is just a mass heater . The heat from the fire is NOT extracted from the combustion chamber. The combustion chamber is insulated so that it reaches very high temperatures producing more complete combustion. The heat is extracted from the exhaust flue downstream of the combustion chamber. This is the design flaw of the majority of wood stoves, heat is extracted from the combustion chamber resulting in a low temperature fire resulting in soot and unburned exhaust gases.

Does anyone know if anyone out there has figured out a way to make a RMS work in a travel trailer as of yet? If so where might I find instructions? I have read several articles that mentioned possibility using the water tanks as the mass but can not seem to find any info from anyone who has tried it. I am knew at all of this but have read a lot. I have yet to see one in action in person though. I am desperate to find an alternative reliable heat source that does not rely on fossil fuels or electricity. I grew up using wood stoves and fireplaces and prefer them over other types of heat but they do require a lot of work and use a lot of fuel ⛽. I love the idea ? behind the RMS and would love to use one if possible in my travel trailer but weight is the obvious issue I am having. Is there anyone that can help me find simple instructions if they exist?

I know there are portable rocket stoves that are mostly used for cooking, but don’t know if they would give you enough BTUs for heating, plus some sort of ventilation would be required. We have a post on portable rocket stoves here.

I just discovered RMH after watching a show. Amd I came across this article while investigating deeper. After reading both the article and the discussions I’ve got a few comments. 1st I think the article needs a small edit. I use to write emissions forms when cars had carbs before computers so I know a little. Combustion produces CO which is bad, CO2 is what is in your glass of soda, it’s what we exhale and plants breath to produce O2. I’m sure the minor mistakes were in the articles used to compile this article and went un-noticed. Now like the CAT on your car Higher temps cause CO to combine with O2 to form CO2 and if you could add say an aquarium air pump hooked to a small metal tube to force more fresh air into the combustion chamber you could lower the emissions even lower but you want it added after the burn process toward the top of the burn chamber so it adds to the exhaust burn-off. 2nd the Steam aspect comes in as the exhaust cools and the left-over Oxy combines with Hydrogen that didn’t burn to form H2O which if any is minor. Now as to Comments: As far as outside air, you wouldn’t want to add an outside air source unless it’s added before your feed box or your fire won’t draft correctly. Now if you add a 3rd chamber outside the burn barrel assembly with an outside air source and a convection out pipe that only collects heat off the outside of the burn barrel and forces it back into the room that would be an add-on not actually part of the furnace, it would be the same as wrapping the burn barrel with copper tubing and using water to supply base boards. As far as weight goes 1 solution is the use of lava rocks in the external heat sink (bench) frame your bench and fill with lava rocks. Their light (some even float) and mix crushed rock with cement powder to seal the rocks into the framework. You can get both lava rocks and lava soil at most supply centers for as low as $1lb. That would reduce your weight considerably. And if you use concrete backer board for the face of your bench you will have a nice surface for tiles. Someone questioned the ceramic radiant heat tubes across the ceiling, walk into any Walmart garden center in the winter and look up to see where the excessive heat is coming from, they also make the little furnace at the input end that burns waste oil from your car and kitchen. But thats something different, I mentioned it because that system has a small fan at the exhaust end that starts the updraft effect. They make inline pusher fans for duct work, something like that could be added to the top of your chimney with a switch next to your stove used to prime your furnace for lighting. It could be off/on or connected to a timer like some gas furnaces that run a few minutes and shut off. Of course it would have to be an all metal fan due to the exhaust heat and require maintenance.

Anyway these are just a few comments and ideas, I hope some help.

Are there also larger radius of curvature stove pipe options available that would work in typical designs?

Chimney pipe is available in a variety of angles (15, 30, 45, 90), depending on the type of pipe. The trick is getting around multiple bends.

Hey, I’m thinking about building my own for green house, but I have to admit the only thing stopping me is not knowing how you clean it. No matter how clean the burn, there will be some soot to clean, and nowhere on web I could not find directions how to clean all those curvy pipes set in masonry. Any ideas where to find directions for cleaning?

You’ve hit on one of the “gorillas in the room” with some of these designs. Our stove has a relatively simple flue with access ports. Many of the designs I’ve seen have no ready access for cleaning. A brush that’s flexible enough to handle the corners would have a hard time putting up with the force required to make it go around those corners. Plan for access ports.

Thanks. That’s the most useful tip I got on this subject.

Lifetime costs and maintenance was a big part of our planning with our home. I’m glad you asked the question.

The rocket stove heater, with pellet hopper, that I purchased, has passed the Underwriter Labratory testing and is insurable in a residence. The family has a factory building them a few at a time. Mine was delivered by truck. I’m very happy with it.0

I have seen a video where an owner tried to bring in air from outside and regulate it with a homemade valve to the burn chamber, I read in the book RM heater builders guide [E &E] they speak of how critical CSA [cross sectional area] should be consistent to the successful operation of the RMH.

so has anyone had success with bringing air in from outside as opposed to drawing air from the room?

the video I saw was on youtube and this family built a earth bag home with the RMH.

we are excited to build one for our shop/studio. we had hoped to have a masonry heater built but finances have been used elsewhere etc. and I am anxious to work with cob.

thanks for the site!!

I think the R.M. needs a few adjustments, if it will perform as they say. Why are they putting the cheep galvanized pipe in all that work. I would use something such as concrete tiles or pipe. A 55gal barrel will last approximately 10 years, if kept inside. The weather is what rusts them out and some stove pollish would help preserve them. I am planning to build one, they seem to be very economical. Seems they just need a little perfection.

The efficient burn does not reduce the amount of CO2 produced (for a given amount of wood). If anything it increases the production of C02. This is not a bad thing however, as the longer chain carbon compounds (smoke) are worse for the environment, and C02 is prefferable.

I would like to build a double layered one, so bench along the bottom, then reading nook higher up. (I had seen a picture of one like this, I think made by a german company) would the bend in the exhaust pipe to get to the second level cause me problems do you think? Also could I then vent it up an existing chimney rather than a horixontal exhaust? Any tips would be greatly appreciated.

The longer the run, the more potential for your fire to not draw as effectively as it should up the chimney. Venting up an existing chimney shouldn’t be a problem if everything is sized correctly, but you should really work directly with someone who has experience building these to make you you get your calculations right.

I wonder what the ratio of the burn tube vs the discharge tube is.

Also does the opening for the fuel/air supply need to be smaller or the same size as the discharge tube (aka chimney tube)?

Any thought about ducting outside air in for combustion instead of using already heated inside air?

PS do NOT allow bots or anyone else access to my name or email address please.

Dr. Mr. Squirrel,

I never sell or use use anyone’s email in any way without their explicit permission. (For instance, if they subscribe the newsletter or to comments.)

You’d need to contact the rocket stove peeps directly for their specific design preferences. Unfortunately, they’re long since given up responding to comments on the post.

Per my experience with our masonry stove, which has some common elements, we do use a dedicated fresh air feed. It has a standard 8 inch diameter pipe for air intake, which then travels down an interior wall and around the stove to wash the glass at the front of the stove. I think our chimney is also an 8 inch, because the stove is located in the basement so the chimney height is quite tall.

Thx for the nice article. I’m down with rocket stoves, totally, but I wouldn’t be happy having to look at something so ugly in my house every day. Do you know of any examples where they have been decorated or camouflaged to look nice? If so, I’d love to see some pics. As you mentioned, masonry stoves are expensive but they can also be built to be beautiful and blend in with a person’s chosen decor.

I’m not sure if the photos in the post weren’t loading for you, but I changed some settings and hopefully you can see them now. You can finish a rocket stove in a variety of ways, as shown in the photos.

Yes and yes. just plan your fireplace or wall. that can incorporate the rmh technology. It could be beautiful.

I live in a cabin built on concrete piers; no way to retrofit a rmh inside. Can anyone think of a way to build the heater outside along an exterior wall and bring heat inside?

The whole point of a rocket mass heater is to keep that hot mass inside the building, so putting it outside is counter-intuitive. If you could put supportive pilings at a similar depth to your current pilings, and put a load bearing concrete slab on top of them, you should be able to put a stove on top of that, but having it outside the building envelope – well, I probably wouldn’t bother with a RMH.

Thanks.

The only way I see is cut out a hole in the floor and install a slab in the ground to support the weight above it .

Seperated by standoff legs and insulated around those legs to minize heat flow from the weight above.

Instead of COB I would be switching to a 275 gal fuel oil tank sitting above floor level and filled with water instead.

The tank would have to be fitted with several heat ducts coiled inside.

Why not build an extra room into your cabin and locate RMH in there?

I live in a residential neighborhood. Does anyone ever have legal problems building one of these for their home or shop? I am seriously considering one for my small shop, one reason is that the chimney regulations for a regular wood stove are really expensive to implement.

You’d have to check with your local building code. My guess is that they would require any sort of combustion device to follow the same guidelines.

How do you get the fire/draft started? Lighting the vertical wood with a cold stove and flue will caused the fire/smoke to back into the house?

For draft getting fire started. Why not replace that costly chinney altogether with a powered draft fan like used on the latest

furnaces. Put it on thermostat control?

dose the RMH have to be ( built on ground level ), we live in a raised house. so what is the weight capacity of a RMH itserlf

Rocket mass heaters, by their nature, tend to be very heavy. Load bearing capacity of the heater itself would vary, depending on materials used and how they are used. It is generally best to build them at ground level. An elevated build would need to be strongly supported.

I don’t know the exact weight of cob but it’ll be close to the weight of concrete

118 lb/cuft

I think an average mass would be in the range of 3000lbs. That’s just the mass not the burn unit.

Some great info on building the rocket mass heater, My question is by super cooling the exshaust gases yo’ll get condesation of water this can be a very powerful acid and how do you work with this also not in you video but others used galv. pipe for thermoal mass flue would this acid water not eat it thru it should flue be ceramic type

Gary you bring up a good point cooling whether slow or fast condenses steam. So far I haven’t see any design with a water trap like power vent furnaces use but personally I would put one in.

The pipe used in the cob benches isnt really required. You could use brick and cement then just cob around it

good information, great pics and video, I like the use of sheet metal and firebricks, thank you so much.

Those are some great pics of mine that were posted in this article of the rmh being built in the wofati we lived in montana.

Could this heat a second floor if the rmh was on the first floor? Or how big of an area could it heat?

Generally, most I’ve seen have been geared to single level/relatively small spaces. We have a traditional masonry stove in our basement, and very little heat reaches the main level from the stove.

I would say a duct/hole over the riser/barrel would cause the heat to rise into upper level. But I’m a newbie 😛

I see no reason why doing a ceiling duct to the second floor wouldn’t work.

When both my wife were growing you we sleep in the upstairs with

a ceiling duct above the only stove in the house before furnaces

I love the rocket mass heater (RMH) concept. I hope to build one someday for my own home. However….

In the section #1, you erroneously state that RMH’s somehow mange to produce less CO2 and more stream which, according to the chemistry of combustion, is impossible.

RMH’s more efficiently and completely burn the wood fuel AND capture more of the heat than conventional wood stoves. But the carbon in the wood CAN’T turn into water vapor (H20). It has to turn into CO2 or CO.

To state otherwise might suggest that a RMH has a smaller Carbon footprint due to less CO2 produced from the wood, which is incorrect. It might have a smaller Carbon footprint because it burns wood fuel more efficiently and captures heat more effectively resulting in less fuel used.

I’m a little late to this discussion but would like to point this out: you’re right but unless its since been edited, the article only claimed “a little CO2” not “less CO2.” Nor does it claim conversion of CO2 to steam.

Granted, not very precise but not the same as claiming what you describe. Also, the only fuels listed are renewable biomass therefore it doesn’t actually have a net carbon emission, basically no carbon footprint at all.

“The sharp turn mixes that smoke with fire so it burns up the smoke! Thus, only leaving a tiny tiny bit of CO2! It’s nearly purely steam.”

I suspect that that is the line that George objected to. I think that because it’s the reason I came down here – to write a similar comment. The implication is that the smoke is burned up, consuming the CO2 and somehow converting it into steam. You don’t wind up with a tiny, tiny bit of CO2 – most of the mass of the exhaust gas is CO2 if you’re burning dry wood.

A later line is clearer, but this one is messy at best.

There is a lot of misinformation being generated here. Sorry.

One of the major by-products of the combustion process chemically is water.

All hydroCarbon fuels contain hydrogen Atoms and Carbon Atoms.

The moisture in wood has zero to do with water as a byproduct though it adds to it.

The process known is fire or combustion with oxygen in the air creates a byproduct with two hydrogen atoms and one oxygen Atom. Also called H2O or water. End of story…fact. Everyone reading this articles posts should do your own homework.

Great article, but the comments are 50-50 in the fact area.

Example… Catalytic heaters which I have one in my motorhome. Are almost 100 efficientin the combustion process. No CO is created only water vapor. The windows and the entire inside a soaked in water vapor after 4 hours. After 5 years im somehow still alive. PS… im a combustion engineer with a degree in chemistry and physics. This is a good article with skeptics posting. Getting the wood combustion to these high temperatures with the extraction of the exhaust gas heat is beautiful.

Still a lot of work.

So, what is being released outside of the home? Will this smoke out the neighbors, or release harmful vapors from burning chemically treated wood? I care about the natural environment and want to be a responsible citizen of my neighborhood…not poisoning anyone, or causing distress to an asthmatic.

Thank you!

Hello, I know this is an old thread, but I’m curious about using this rocket heater design with other fuel sources. Specifically, can it be used with natural gas? I understand that this might defeat the purpose of using a cheaper fuel source, but I’m interested in knowing if it’s technically safe and if it would burn natural gas (or other fuels) more efficiently than commonly used devices.

By comparison, natural gas heating systems already tend to burn fairly efficiently (you don’t have the solids of wood burning) and you would have to ensure that the exhaust gases retained enough heat to exit the structure and not hang around in a chimney, potentially leaking back into the home. It’s not a simple matter of substituting one fuel for another. To couple thermal mass with natural gas, a more typical approach would be something like a boiler with heat exchanger providing heat for in floor radiant heating.

I also like the RMH concept. But let’s do some thinking here.

All mass heaters have warm the mass first before you get warmed.

the heat is delayed. So if you come home from work expecting a cosy nest

you’re going to wait till the mass gets warmed up. Unless someone has keep it up.

If you are thinking of putting a RMH in anything movable, expect cracks, because

the more ridge the mass will be more brittle.

We have a large masonry stove, and that retains heat for over 24 hours. Not sure about the heat retention on these types of units.

When you say yours retains heat for 24 hrs.

several questions

How many cubic feet of COB ?

What outside temp?

Take a infrared thermometer and give me some reading.

The hottest and lowest temp of the mass.

Please

My masonry stove is a Tempcast kit with brick facade, no cob. Outside temp never gets so hot that I can’t comfortably touch it. I would estimate that hottest mass temp in the low 100s, and lowest mass temp is house temp because it’s in the center of the home.

If you burn less wood, you create less CO2. It’s the most efficient way to generate heat from a fuel source, so it will produce less CO2.

I am investigating turning a small horse lorry into a tiny house, and wondering if it would be possible to incorporate a small version of a Rocket Stove fur cooking and heating such a small area, without using the cob?

The trouble with what you propose is that to cook on a rocket stove without the oil barrel is that one normally would cook over the heat riser and you would end up with a smokey truck. If you had the barrel over the riser you could cook on the top of it and you would need to vent the exhaust from the base and take a stack out of the side [or roof] of the truck. You would be losing most of your heat that way as the point and effect of the mass is to retain the heat for a long time. If you just exhaust straight out most of the heat will escape with the draw up the flue.

Matt Walker has a RMH that he uses to cook on, He is one of the pioneers in the field, see link below to his “tiny masonry cook stove and heater”

http://walkerstoves.com/tiny-masonry-cook-stove-plans.html

i love the idea of building a rmh in the cabin i’m starting but i don’t have room to build a bench like most of these show do you have any sugestions?

You could use it for radiant heat flooring.

There are variants that use a masonry (brick) “bell” which is basically a hollow area in which the hot air stratifies with its exhaust at the bottom of the bell. These can be built vertically and have a footprint of approx. 2.5 x 3.5 foot and about 4-5 foot tall. It’s like standing the bench on end. Care should be taken in the area of initial exhaust area using firebrick. Internal routing of the hot air inside the bell would first go through the firebrick/refractory cement area and be cooled enough so that common red clay brick (not cement brick) will be used for the outer walls of the bell.

There are batch style RMH burn boxes that take less fueling and wood prep compared to a J or L type

I have been looking at RMH for some time. We recently moved into a house with an brick fireplace that has what I am guessing is a mass heater on the side. At one point the fireplace had a gas insert installed. I am wondering if this fireplace could be converted to a RMH. Can anyone lead me in the right direction?

I’d tried inquiring with a local heating contractor to identify what’s going on with your unit, or searching for rocket mass groups in your area. Offhand, that doesn’t sound like an RMH setup, but it’s impossible to say without being able to look the whole thing over in person.

Great article. I haven’t made a heater yet, but have used the “J” to make a great BBQ grill. It’s a “J” made of black sheet iron stovepipe with a BBQ grill at the top of the J supported by a stand, and it’s inside a woodshed that is covered by a roof but is mostly open to the outside air. I use kindling sized wood and dried plant stalks as fuel and grill every Sunday for me and my GF. The unit works great. Getting it to draft is tricky sometimes until the “rocket effect” starts, then it’s great from then on.

We have a similar effect in our Tempcast masonry stove. The draw isn’t terribly strong until it gets up to temp.

I’ve seen RMS idea applied to greenhouses.

Why not move that heavy COB mass to the basement and take the heavy load off the floor?

You could raise the heated mass to 160-200F reducing the mass. And draw off that mass as needed.

Use water instead. set up like a hot water boiler system?

because. 1cu/ft concrete 1 degF stores 23 btu wear as 1 cu/fi water weights 62 lbls/cu ft giving 2.7 times more

per cu ft.

500 gal insulated water tank x 8.34 x 90deg could allow 15000btu/hr for a whole day.

OR

use (2) 275 gal fuel oil tanks.

Plus use a power vent system if needed. Still the RM heating part to get a clean burn.

I think the most important part is to burn all the fuel completely before any heat is passed to a heat exchanger.

Moreover

Chimneys depend on temp difference from top to bottom for a draw.

I prefer a stainless steel ceramic wool wrapped. min mass to warm up.

I don’t know min temp needed for a good draw but I’m searching.

one problem is getting a chinney draw with a cold mass. Some have used a temp bypass

in their flue. i think it could be setup with a bimetal coil to automaticly control min flue temp.

Using (2) 275 tanks could make it a gravity heat flow. But the tanks would have to be modified

with heat tubes welded in to heat the water.

I have a rocket stove that has a pellet hopper and is gravity fed. I love it. It heats my home easily. I’m 72 so chopping wood is out of the question. My stove is able to burn sticks 2 1/2 ft long by up to 2″ around. But with the hopper set in the feed tube it holds a bag of pellets and lasts 24 hours.

It doesn’t have the heat mass to radiate heat but each style has its strengths. For this great grandma my heater is perfect. It has the double walled heat collection chamber. Its fabricated of Harvey metal. It can draw air from indoors or with pipe added it can draw from outside. The flat top of the outer chamber is 16″ across. I keep 3 gal of water hot on top and I can heat food or cook on top. At the side of the burn chamber there is a wide metal lip where I keep a tea pot warm on one side and a tall 2 1/2 cup covered pot of coffee or soup repeats. I keep an old small mental roaster to catch ashes in when i clean the burn area. This stove is sold with a long handled scraper to clean out ashes.

If my home is cold when i start a fire I have a 7″ fan that I turn on to blow on the heat chamber and start moving heat through the home. At -16 this winter my mobile home (16×56) stayed comfortable.

Thanks for this useful info! I like the idea of a gravity fed pellet situation.

I like switching to continious pellet feed idea. regular RMS design sound good till I realize I ‘m going to chop the wood smaller. Feed it oftener. Cause there’s not enough mass to store enough heat all night. Sedore stove Canadian, and Tarm boiler made New England area. both top feed and bottom burn sideways. And use secondary air to complele combustion. As far as the claim it saves wood compared to what ? A fireplace ? I give credit to the newer stoves (Vermont Casting line) having a much higher effenency the the old style. I seriously doubt RMS claim do much better. Factories using coal. Power it to dust and blow it into a fuelized chamber not air controlled but fuel controlled. burn very effecent.

Thanks with your info with your gravity fed pellet hopper!

Is there any noise generated by a RMH? I’ve never actually seen one in operation, and heard that the strong draft is what gives the “rocket” in the name…

I don’t have a standard rocket mass heater, but I do have a masonry stove, which is similar, and it’s no noisier than a normal fire.

The sound is hard to describe. It’s not exactly noisy, it’s just the sound or air being pulled into the pipe, and the burning wood crackling, which in the case of my BBQ grill is a six inch pipe. You could almost compare the sound to a woodstove door left wide open while the fire is burning inside it, but as the fire area of the “J” is so much smaller, the sound is less than that. Also less noisy than say, an open fireplace, again because the fire is much smaller.

Thanks, Dan.

Hi Laurie,

Do you know any one can

build me a rocket mass heater from start to finish.

I am so excited about the

concept come with the

bench. I live in Colorado.

Thank you!

I’m a novice in the rocket mass community, but hopefully some others who are watching this comment thread may have some suggestions.

Did you ever build your RMH? I live in Black Forest and am curious. Thx!

I live in Black Forest, CO and am slowly building my dream after total loss of my home during the 2013 wildfire. I plan to build one, hopefully in the coming year and hope to offer a shared experience. There is a healthy group of similarly-minded folks around. Stay in touch, please. Any others nearby?

I am slowly rebuilding after losing my house in the 2013 Black Forest (Colorado) fire. I hope to give this a try and am willing to share my experiences. Any others nearby interested in collaborating?

I am an engineering intern will help with rocket mass stoves.

What about carbon monoxide? Is that an issue in a well insulated home? I guess you safe a lot of fuel, but its still an open fire in your home.

Has anyone experience with this issue?

There is no carbon monoxide able to get in your home with a properly built mass rocket heater. The exhaust is forced out of the home by design. For technical details watch some of the youtube videos. Thx

As Rudy notes, the combustion gases should remain contained within the unit until they exit the dwelling. Here’s a demonstration:

Do you have a book on mass rocket stoved?

How much do they weigh?

Sand filled for eg.

The couple featured in this post did put out a book, “The Rocket Mass Heater Builder’s Guide: Complete Step-by-Step Construction, Maintenance and Troubleshooting“.

Weight varies greatly depending on the materials used and design of the stove, but a typical rocket mass heater’s masonry may weigh 3–6 tons.

What I would like to know is how does this affect the neighbors? The environment? If someone burns wood that was treated with chemicals such as paint or formaldehyde, does that go out into the neighborhood and poison the environment? Or is it all contained in the heater and turned to ash? I would think that the fumes and smoke have to go somewhere. I have sensitivities to smoke and chemical odors, so before I consider making one of these for our home, I really need to know! 🙂 Thank you!

I personally avoid burning anything chemically treated. Even if it were contained in the ash, I use my ash in my gardens and orchards.

There is no “away”.

1 Pressure Treated 2x6x8 has enough cyanide to kill 250 humans. DON’T EVER BURN PRESSURE TREATED WOOD IT CAN KILL YOU!!! Wood additives can range from Deadly to unknown when burned. Poison will contaminate the Stove, air, ash and you.

Any combustion can and does produce carbon monoxide. These kinds of stoves are worse than a regular wood stove because the exhaust has little odor. These stoves are often home made and the exhaust is so cool it may settle in a low place. This is circular reasoning at it’s finest. If it poisoned you it was improperly built, if it was improperly built if poisoned you. Get a bunch of carbon monoxide detectors and use them all over. There are to many variables wind directions trees roofs that can cause freak conditions, and gas build up.I like rocket mass heating but it is not a saint. It will you as dead as any other combustion

I have one in my home. You must remember that carbon monoxide is flammable to when heated in these things so it gets burned up

I’m quite familiar with rocket stoves and variations on that theme because I’ve built several. I just wanted to let you know how much I appreciate the this clearly written piece on the subject. Well done.

Mark

Glad you approve.

in a RM heater: How is burn rate controlled? By the amount of wood burning at the time?

modern wood stoves like Vermont Casting add secondary air which completes combustion without

increasing burn rate. On RM how is this handled?

With our masonry stove (which is similar), there is no controlling the burn. The goal is to burn as hot and fast as possible, and then close down the chimney and fresh air feed, trapping the heat in the masonry. The masonry then slowly emits the heat over time. Ours stays warm for over 24 hours, but we burn twice per day in cold weather to boost the output as high as possible. It’s not recommended that we burn any more than this, as there is only so much thermal capacity in the masonry.

I’ve built serveral waste oil burners and know how quickly a steel unit burns out

and I’ve checked the max temp at 1050 max using my infrared thermometer.

and had to replace it yearly.

I know that 50 gal barrel going to burn thru quickly as well. But it appears none

has used the designed long emough to get a feed back on what problems lay ahead.

I’m with you. I know plenty of people use 50 gallon drums for burn barrels, and eventually those fall apart, and conditions in a burn barrel are a lot cooler than a rocket stove. I offer space for alternatives here on the site, because I know a lot of people want less expensive DIY options. In our home, we went with a refractory cement masonry heater kit with brick facade, and there has still been settling and decreased burn efficiency over the years. (Our chimney guy has been working to find and seal all air leaks each year when he comes out.)

I’m seeing pictures of RM with barrel matted in with COB

And I’ve noted few recent posts. Makes me wonder if there’re not

many interested in RM because it’s not insurable or meeting building regulations.

I got a plumber who heats his shop with a 12in dia infra red tube running along 2.5 ft under

the roof level but above all else under it.

I like that idea as an alternative and forget the mass feeding continually with pellets.

but using the burn chamber.

A lot of alternative building techniques have a tough time meeting code/getting insurance. Of course, many willing to build that way are also inclined not to have insurance/be off grid/unregulated.

The IR tube transfers heat well to the rest of the building? It doesn’t just give a hot spot near the ceiling?